4 Koji making

The heart of the brewing process.

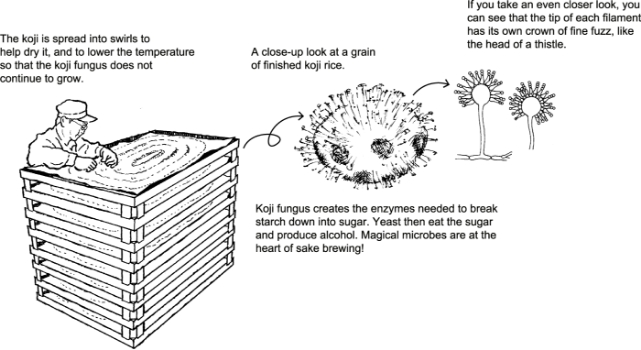

Sake may seem similar to wine in appearance and taste, but the way it is fermented is actually closer to beer, because the raw ingredients of beer and sake are starchy grains, not sugary fruits. Yeast cannot eat starch, so the first step in making beer and sake is to break down the starch into sugar that the yeast can eat and turn into alcohol.

For sake, the rice starch is broken down to sugar with the help of a fungus called koji. When the koji fungus is grown on steamed rice, it creates the enzymes needed for this magical conversion. How the koji is grown strongly influences the flavor and quality of the sake, so great care is taken during the two days required to cultivate it. The brewers apply a combination of science and hard-earned skill to raise each batch of koji with all the care you’d lavish on a new-born baby.

Day one.

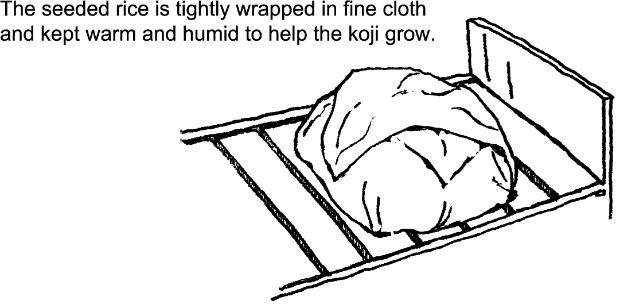

On the first day of koji making, a 20% portion of the rice steamed that day is moved into the koji room and sprinkled with powdery koji spores.

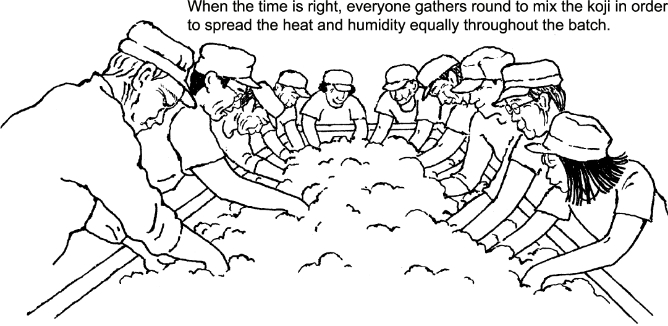

In the afternoon, the batch is hand-mixed to spread the heat evenly.

Day two.

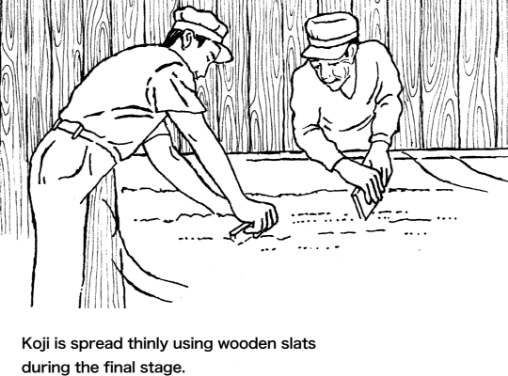

On the morning of the second day, the koji is moved into a special box called a tana. The koji is now said to be at its peak. In the afternoon the koji is spread thinly on a heated table to aid in evaporation. Great care is taken to avoid sudden rises in temperature. At about 7:00 in the evening this process is complete and the koji is given its final handling.

Day three.

On the morning of the third day, the steaming koji is taken out of the koji room into the cold brewery. The brewers then spread the koji in swirling lines on trays. The perfectly cultivated koji, packed with the enzymes needed to break starch to sugar, is ready to be added to the various fermentation tanks.