7 Filtering

Filtering the sake must be slow and gentle.

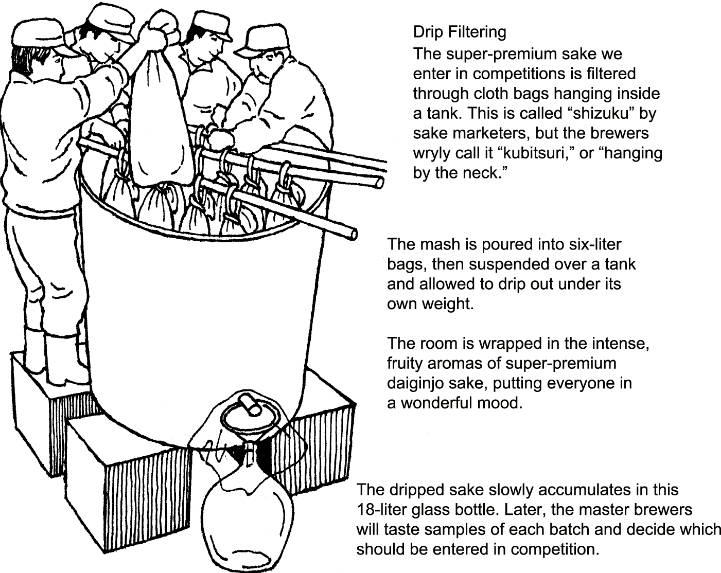

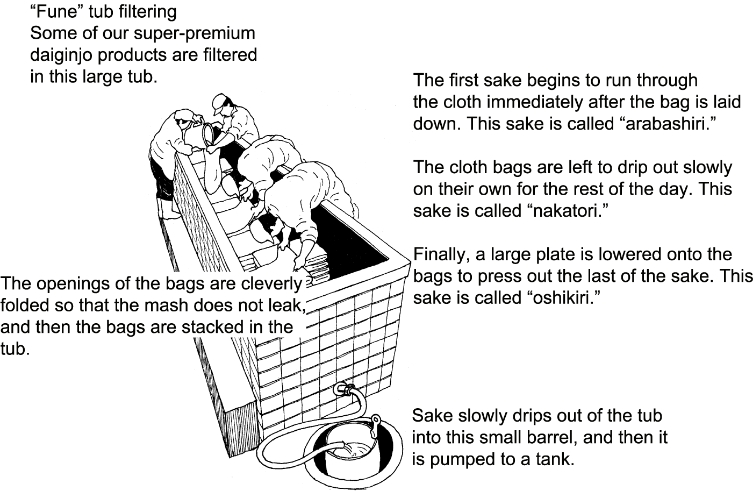

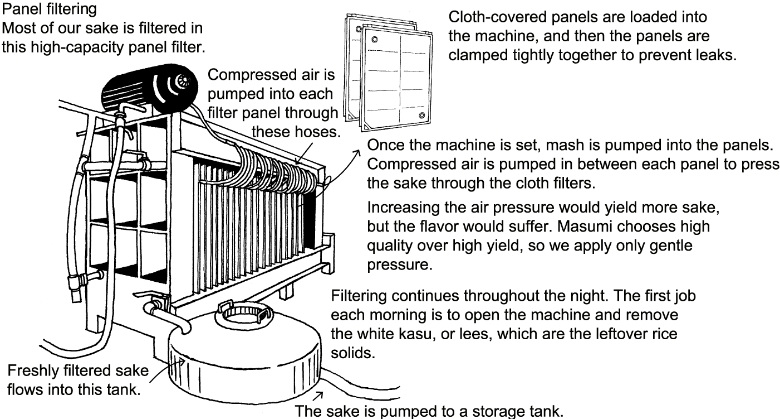

After about 25 to 30 days, the mash so carefully fussed over by the brewery workers has reached the appropriate amount of alcohol, the aromas and flavors have fully developed, and the mash is ready to be filtered. We use three methods for filtering, depending on the quality and the quantity of the sake. We filter super-premium sake made for competition by pouring the mash into cloth bags, which we then drip into tanks. For some super-premium products, we stack these same cloth filter bags in a deep tub called a “fune” and apply gentle pressure. For sake we make in larger volumes, we use filtering machines that employ compressed air to very gently press the mash through cloth panels.

With the exception of limited seasonal varieties that are bottled and shipped right after filtering, most sake is aged in tanks or bottles for between six months and a year before it is sold. Depending on the style of the sake, a variety of post-filtering techniques may be applied before final packaging, such as micro-filtering with charcoal, pasteurizing, and diluting with water to lower the alcohol content.